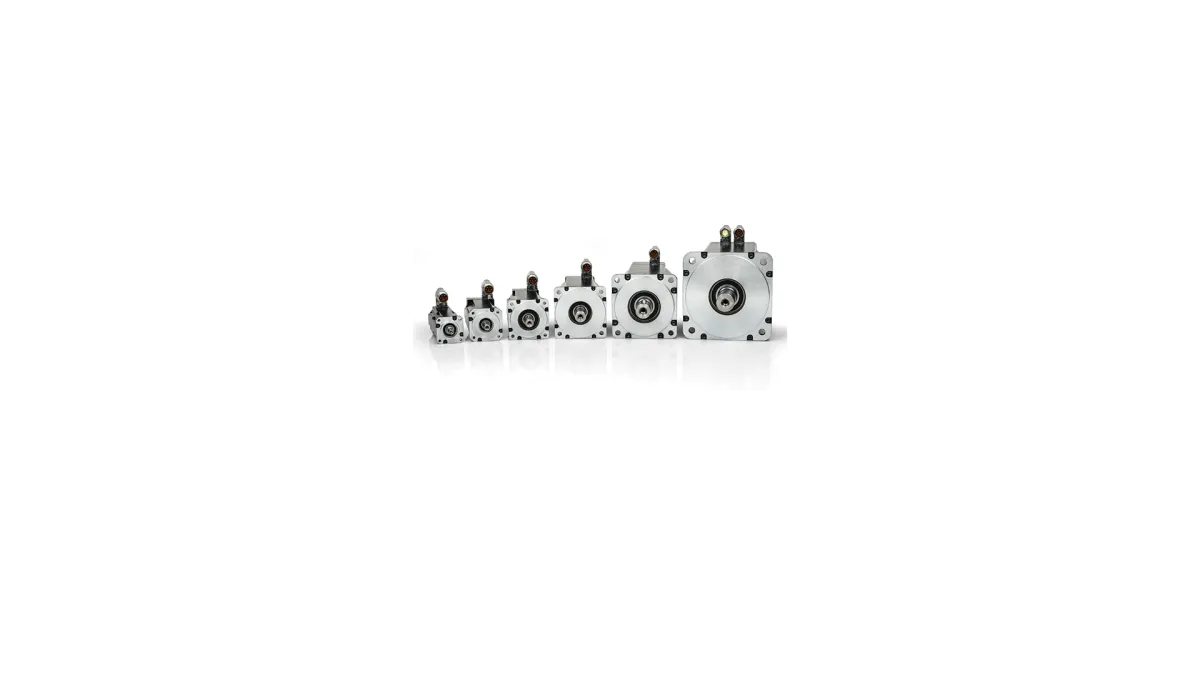

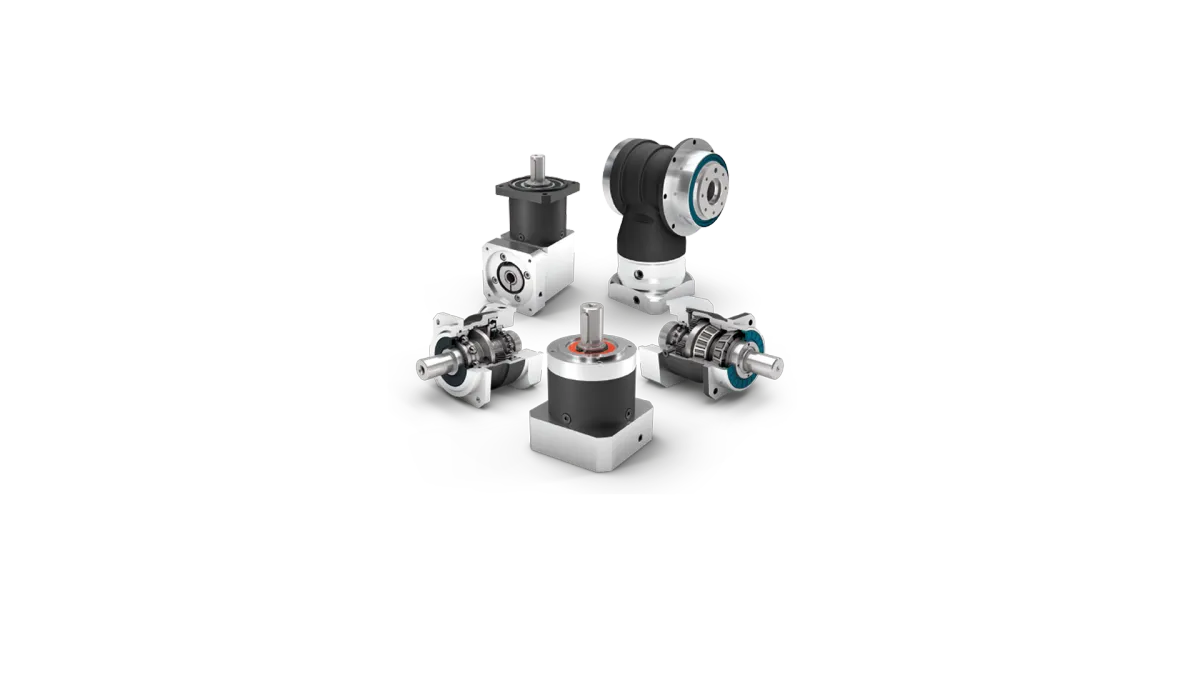

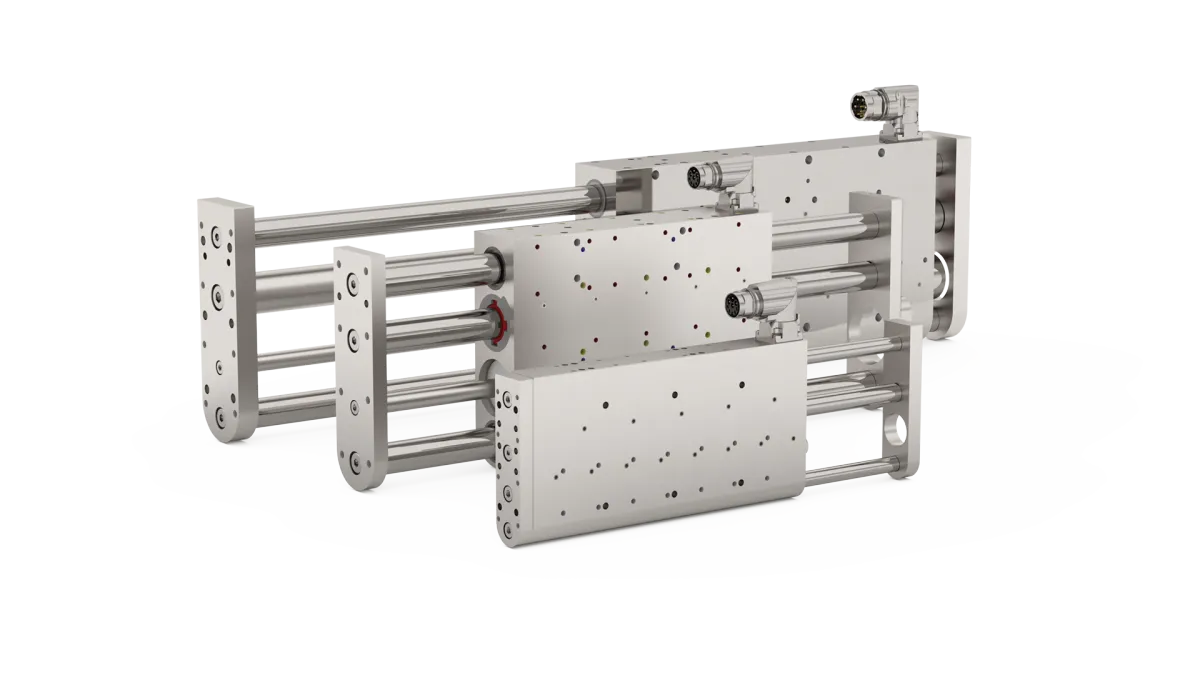

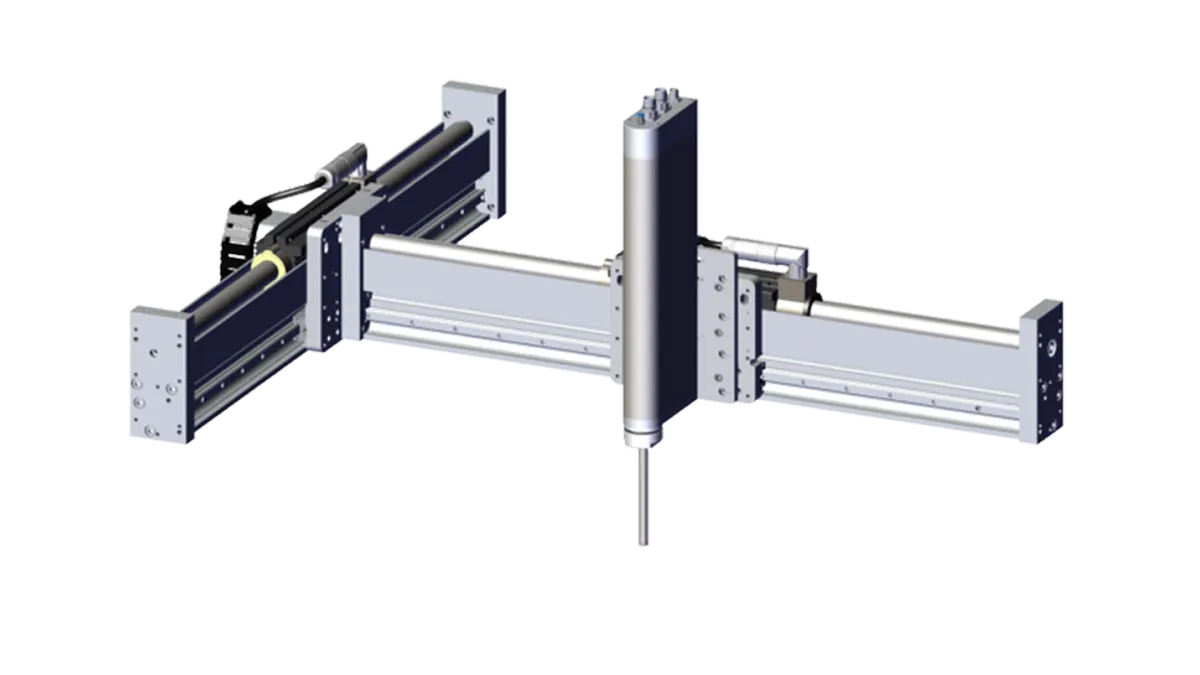

Servo Motor Systems, Stepper Motor Systems, Drives, Planetary Gearboxes, Motions Controllers, PLCs, HMIs, Controller Software, Panel-IPCs and more...

Contact Us

+46 (0)42-38 08 10 [email protected]

+46 (0)42-38 08 20 [email protected]

+46 (0)42-38 08 00 [email protected]

Address

SDT AB

Sabelgatan 4

254 67 HELSINGBORG, SWEDEN

Legal

© SDT AB 2025. All Rights Reserved.